Crimped Wire Meshes

Price 92 INR/ Kilograms

Crimped Wire Meshes Specification

- Aperture

- 6 mm to 100 mm

- Wire Gauge

- 12 to 22 SWG

- Length

- 30 m (standard roll), customizable

- Hole Shape

- Square or Rectangular

- Surface Treatment

- Galvanized, PVC coated, or self-color

- Product Type

- Crimped Wire Mesh

- Mesh Type

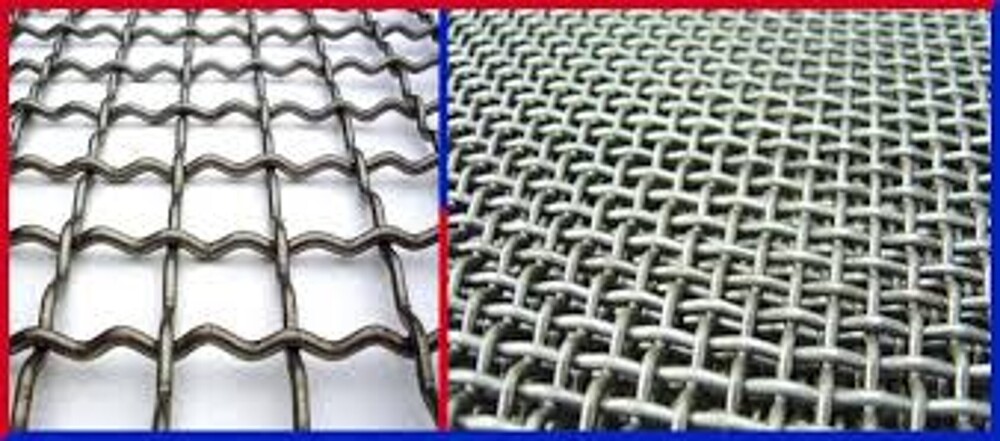

- Pre-crimped, Double-crimped

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel, Mild Steel, Galvanized Iron

- Alloy

- Available in SS304, SS316, low carbon steel

- Application

- Mining, Quarrying, Fencing, Sieving, Filtration, Construction, Industrial

- Dimensions

- Width 0.5 m to 2 m, Length up to 30 m

- Wire Diameter

- 0.5 mm to 2.5 mm

- Weight

- Varies as per size and material, approx. 120 kg/m

- Color

- Natural metallic, green, black (on request)

- Tensile Strength

- As per material and gauge, high tensile available for heavy-duty

- Standards

- ASTM, DIN, or equivalent available

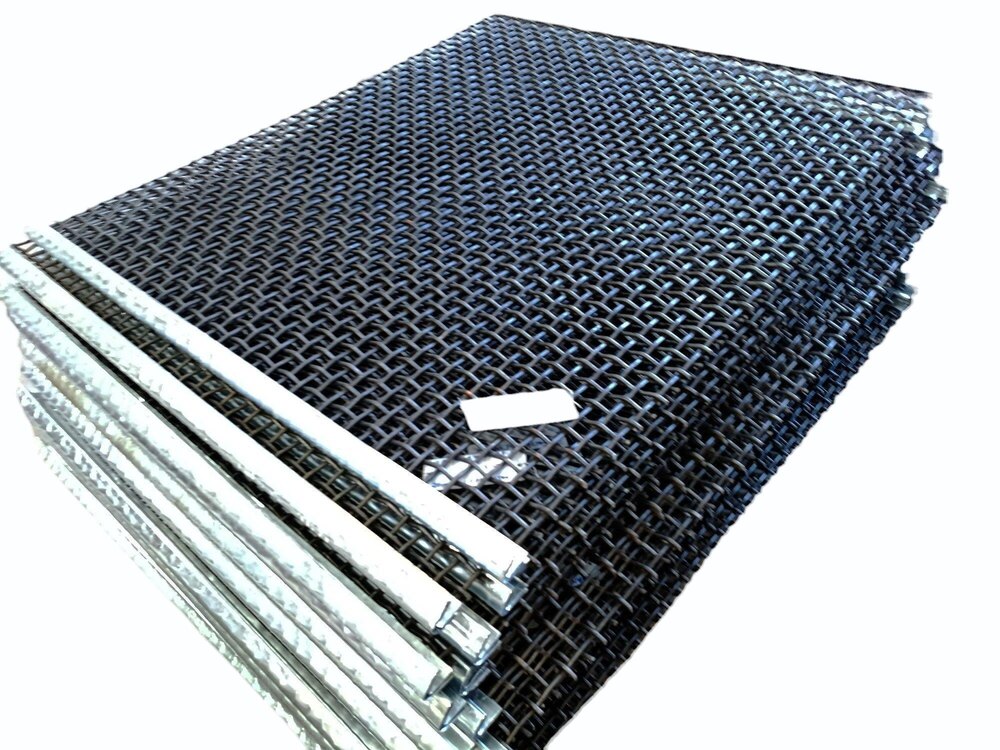

- Packing

- Rolls or customized as per order

- Operating Temperature

- Up to 800°C depending on material

- Weave Type

- Double Crimp, Lock Crimp, Flat Top

- Finish

- Rust-resistant, corrosion-protected

- Open Area Percentage

- 30% to 85% as per mesh size

- Edge Type

- Cut edge or folded edge

Crimped Wire Meshes Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 100 Kilograms Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Crimped Wire Meshes

| Material | Carbon Steel |

| Opening Size | 8 Inch |

| Crimp Style | Lock Crimp |

| Hole Shape | Square |

| Mesh Number Size | 50 |

| Surface Treatment | Hot Dipped Galvanized |

| Color | Black |

| Usage/Application | Mining Industry |

MaterialCarbon Steel

Opening Size8 Inch

Crimp StyleLock Crimp

Hole ShapeSquare

Mesh Number Size50

Surface TreatmentHot Dipped Galvanized

ColorBlack

Usage/ApplicationMining Industry

Crimped Wire Meshes into a structure resembling a grid produces stainless steel wire mesh, a resilient and corrosion-resistant material. It is employed in numerous applications, such as

Additional Information:

Production Capacity: 10000

Delivery Time: as per order 10 to 25 days

Crimped Wire Meshes into a structure resembling a grid produces stainless steel wire mesh, a resilient and corrosion-resistant material. It is employed in numerous applications, such asAdditional Information:

- Production Capacity: 10000

- Delivery Time: as per order 10 to 25 days

Customizable Meshes for Versatile Applications

Our crimped wire meshes are engineered for flexibility, accommodating demanding requirements in sectors such as mining, construction, and filtration. Choose from various weave types, edge finishes, and wire gauges to achieve the desired aperture, strength, and corrosion protection. Tailor your order to specific needs, with a range of surface treatments and color finishes to suit distinct environments and functionalities.

High-Performance Materials and Standards

We offer meshes crafted from premium stainless steel, mild steel, and galvanized iron, designed to operate in temperatures up to 800C. Each mesh type adheres to international standards like ASTM and DIN, ensuring quality, safety, and performance. Stainless steel grades like SS304 and SS316 provide superior corrosion resistance, extending product life in even the harshest industrial conditions.

Reliable Distribution and Custom Packing Solutions

As a trusted distributor, manufacturer, and supplier in India, we provide reliable logistics and packaging options, including standard rolls and highly customized packing to match client requirements. Whether you need bulk shipments for industrial projects or specialized packaging for unique applications, our tailored solutions ensure safe delivery and product protection.

FAQ's of Crimped Wire Meshes:

Q: How are the crimped wire meshes manufactured and finished for durability?

A: Crimped wire meshes are woven using pre-crimped wires in double crimp, lock crimp, or flat top styles, and available with cut or folded edges. The meshes are treated with rust-resistant coatings, including galvanizing or PVC, and can be supplied in natural metallic, green, or black to enhance their durability and suitability for both indoor and outdoor applications.Q: What materials and grades are used in these wire meshes, and how do they impact performance?

A: The meshes are made from stainless steel (including SS304, SS316), mild steel, or galvanized iron. Stainless steel options offer excellent corrosion resistance and are suitable for high-temperature and aggressive environments, while mild steel and galvanized iron provide cost-effective solutions for less demanding conditions.Q: When should I choose a double crimp over a lock crimp or flat top mesh?

A: Double crimp is ideal for standard industrial applications requiring robust mesh with good rigidity. Lock crimp provides higher stability for heavy-duty tasks, as the wires are securely locked in position. Flat top mesh delivers a smooth surface, making it preferable for conveyors or applications where material flow is crucial.Q: Where can crimped wire meshes be used, and what industries benefit from them?

A: These meshes are extensively utilized in mining, quarrying, construction, filtration, sieving, fencing, and other industrial sectors. Their customizable nature allows them to meet the specific requirements of diverse applications, from heavy-duty screening to decorative or protective barriers.Q: What is the customization process for dimensions, finishes, and packing?

A: Customers can specify mesh width (0.5-2 m), length (up to 30 m), aperture size (6-100 mm), wire gauge (12-22 SWG), and surface treatments (galvanized, PVC coated, or self-color). Packing can be standard rolls or custom formats as per order to ensure optimal transit and storage.Q: How does tensile strength and wire gauge affect the suitability of a mesh for heavy-duty applications?

A: Tensile strength depends on both the wire material and gauge. Heavy-duty tasks require high-tensile options with thicker wires (lower SWG numbers), ensuring that the mesh resists deformation under load and can withstand harsh operating environments.Q: What are the benefits of choosing a crimped wire mesh with rust-resistant and corrosion-protected finishes?

A: Rust-resistant and corrosion-protected finishes prolong the service life of the mesh, maintain structural integrity, and reduce maintenance costs. These treatments are essential for applications exposed to moisture, chemicals, or extreme outdoor conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Screen Category

6mm Spring Steel Wire Mesh

Price 95 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Wire Gauge : 6mm

Wire Diameter : 6mm

Aperture : Varies (customizable)

Material : Other, High Carbon Spring Steel

Refractory Spring Steel Wire Mesh Screen

Price 95 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Wire Gauge : 2 mm to 12 mm

Wire Diameter : 2 mm to 12 mm

Aperture : Varies by mesh size; standard 10 mm to 80 mm

Material : Other, Refractory Spring Steel

Spring Steel Slot Hole Jali

Price 95 INR / Square Foot

Minimum Order Quantity : Spring Steel Slot Hole Jali100 Square Foot

Wire Gauge : Available in 10 SWG to 25 SWG

Wire Diameter : Varies from 0.5 mm to 2.5 mm

Aperture : Customizable as per requirement

Material : Other, Spring Steel

Coke Plant Spring Steel Wire Mesh Screen

Price 135 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Wire Gauge : 2.5 mm to 12 mm

Wire Diameter : 2.5 mm to 12 mm

Aperture : 5 mm to 100 mm

Material : Other, Spring Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free